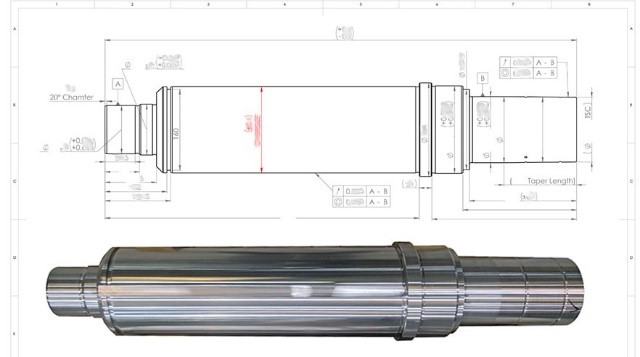

Reverse Engineering

There are several highly qualified engineers working at Innovation Electric who have proven their technical abilities by reverse engineering the manufacture of a motor without having access to any OEM drawings.

Our engineers have made their own CAD drawings, which have been approved by the client and the motors manufactured

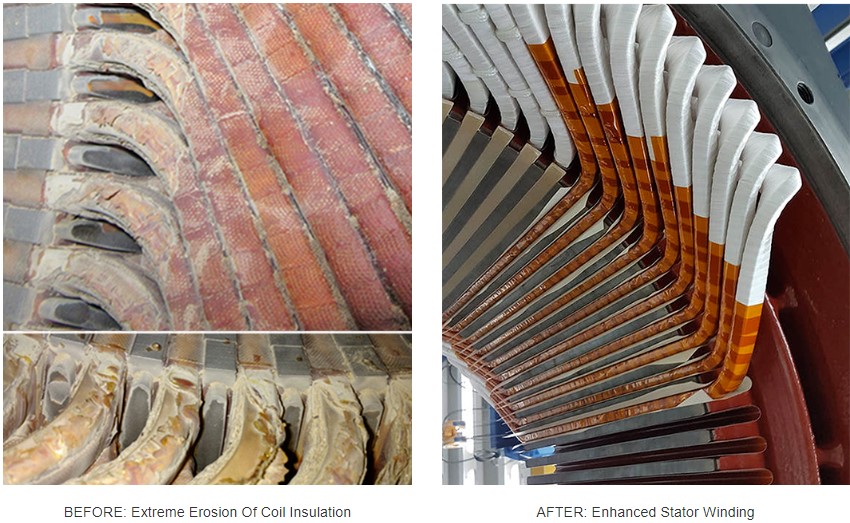

Motor Enhancements & Re-Design

We have focused our business on Transforming Traction to provide performance, reliability & security to our customers assets. Our innovative approach has resulted in:

- Increase in Motor Efficiency

- Reductions of Energy Consumption

- Improving Reliability

- Increasing Cost Efficiencies

Rewinding Stators and Armatures, as well as building New Rotors, without manufacturers drawings if required, are a particular speciality of ours.

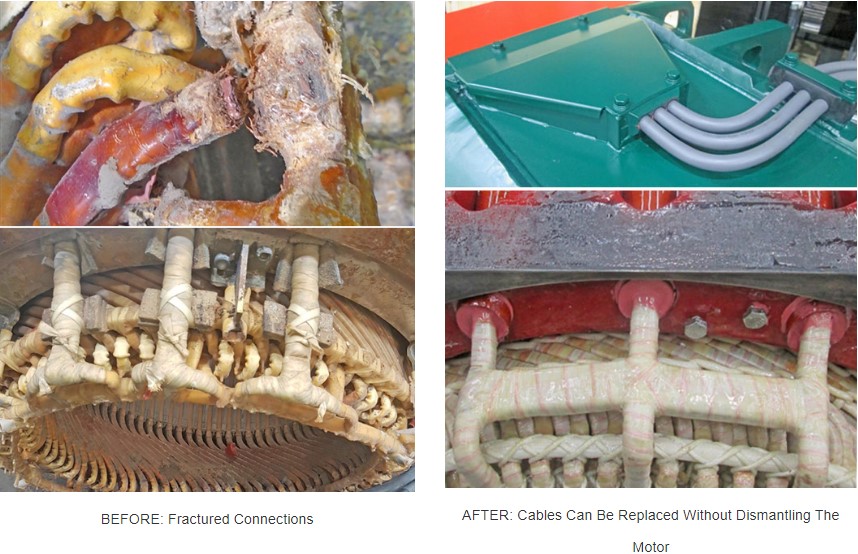

Problem solving

We take pride in our engineering capabilities, technical knowledge and our reputation for quality workmanship which sets us apart from other maintenance providers.

- Increased Motor Stability

- Improved Resistance to Vibration

- Reduced Copper Wear leading to Longer Brush Life

- Longer Commutator Life-span

- Greater Resistance to Flashovers

- Reduction of Water, Snow or Sand Ingress

Comprehensive industry leading warranties we include with our work, give our clients extra comfort when dealing with us.

Results

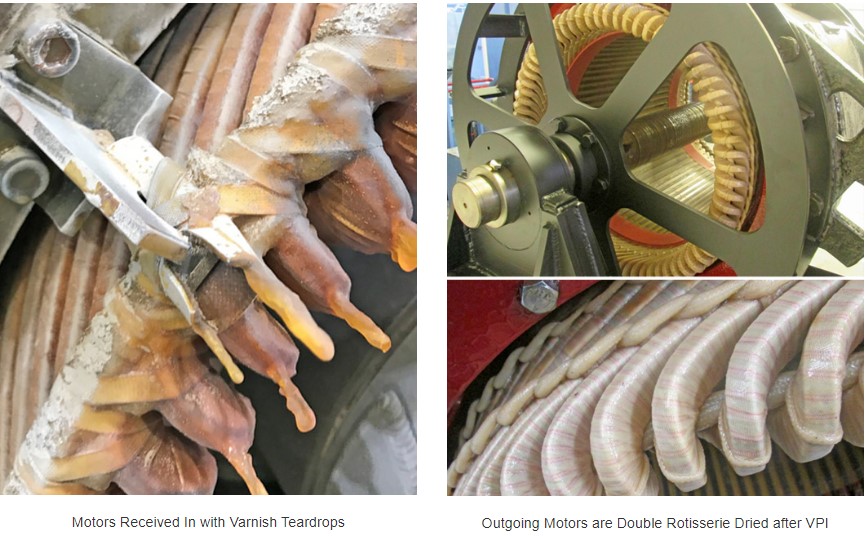

Our stringent in-house testing procedures, full accreditation and adherence to all International Standards of Quality Assurance, Health & Safety, and Environmental Management, ensures the highest quality and reliability of our work. The application of these enhancements all contribute to an improvement in the performance of Motors delivered back to clients from Innovation Electric,

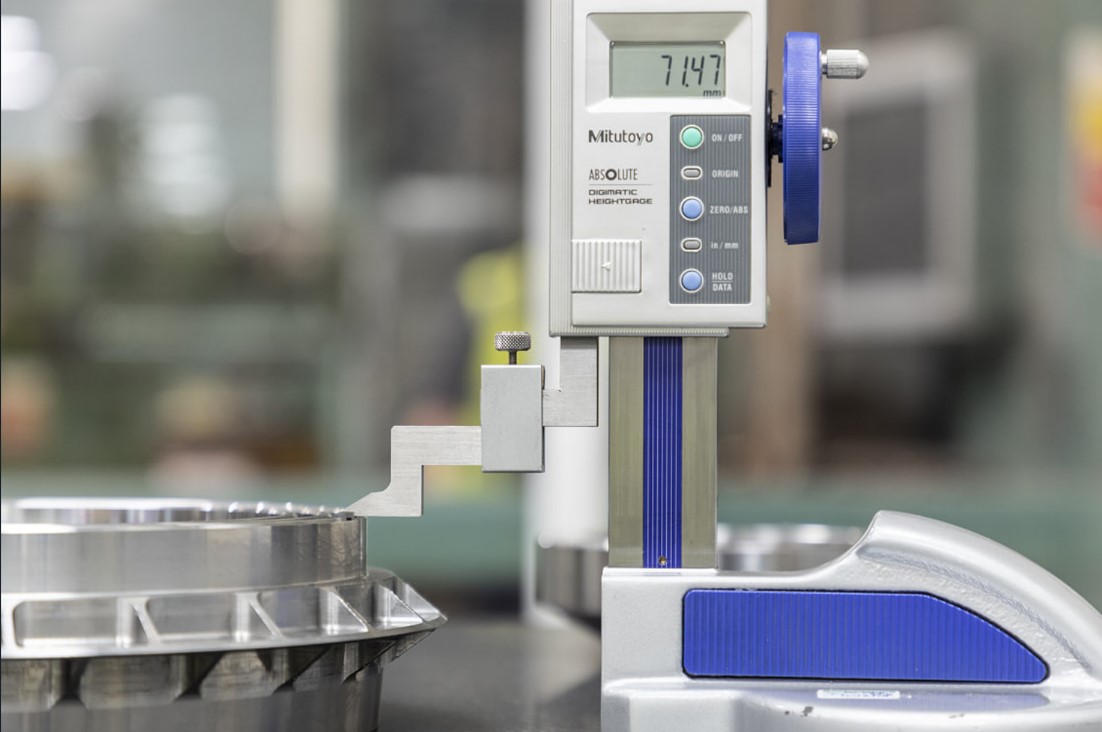

Quality Control

Every part that goes into your motor is built to be equal to, or in many cases better than OEM specification. All components are quality tested by our dedicated Quality Control team in a temperature-controlled environment.

Testing

Before any motor leaves INNOVATION ELECTRIC it is thoroughly tested at several stages of rebuild / rewind / overhaul, including:

- AC Hi-Pot test

- DC Hi-Pot test

- Bar to Bar surge test

- Resistance (Bar to Bar) test

The time taken in our rigorous testing makes every Traction Motor we send back to you more reliable. When our comprehensive testing is put together with the top-quality materials we use, it makes the motors last longer until their next servicing, helping you to lower your maintenance and life-time costs.