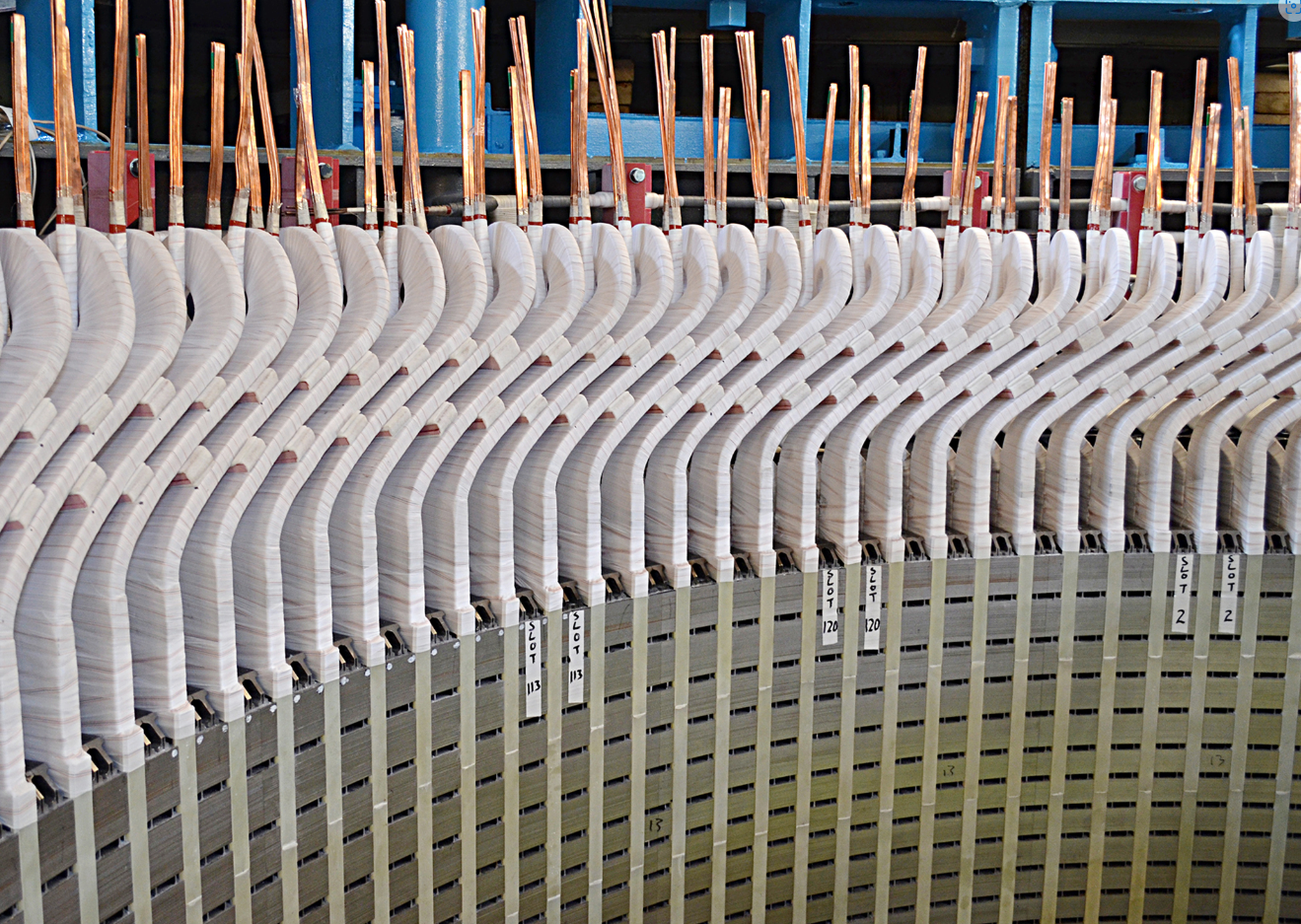

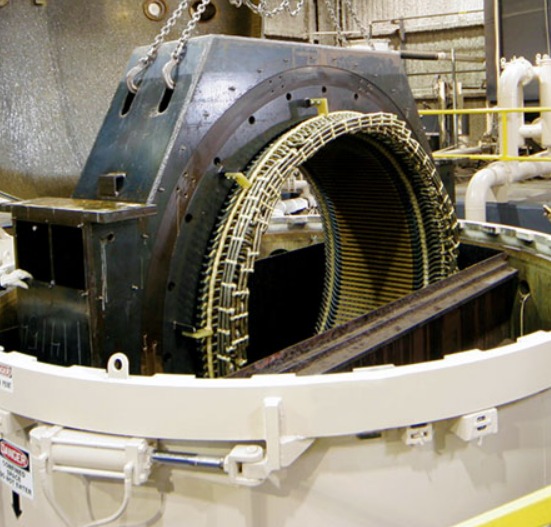

Dimands Coils

Innovation Windings manufactures an extensive range of high voltage motor and generator coils to an approved in-house specification. Our Diamond Coil offering range from 400v to 11kV with both resin rich and VPI insulation options.

We work with clients across a range of industries, covering everything from traction to power generation. Our products are all manufactured to the highest standards and we pride ourselves on providing a responsive service with quick delivery times both in the IND and abroad

Insulation Systems

- Hot Pressed Resin Rich

- Un-pressed Resin Rich

- Vacuum Pressure Impregnation (VPI)

Conductor Materials

- Copper Grade C101, BS1432, Cond “O”

- Mica / Film

- Nomex

- Enamel / Dacron

- Enamel / Mica

- Enamel / Glass

- Mica / Glass

Main Insulation Material

- Mica / Film

- Mica / Glass

- Mica / Glass / Film

- VPI

Corona Discharge Protection

- Semi Conductive / Stress Grading Tape

- Conductive / Corona Shield Tape

Resin Rich v VPI

A question Preformed Windings are often asked is which specification of coils is more suitable for high voltage applications, VPI or Resin Rich. We hope to outline some of the advantages of each below, although it should be noted that we manufacture both VPI and Resin Rich coils for our customers:

Resin Rich Advantages:

- Highly uniform impregnation of the resin in the slot portion reducing the risk of partial discharge occurring

- Rigid resins are used in slot cell section of the coil and different resins with resilience to coil movement are used in the endwinding i.e. resin containing flexibilisers

- Capability to control partial discharge in the slot, and remedial action in service is practical during insulation system life

- Partial repairs are practical i.e. coils which have failed can be replaced

- Coils can be installed on site as there is no requirement for further processing (i.e. the VPI process)

- Endwinding bracing systems can be improved & made more robust to meet operational requirements

Resin Rich Disadvantages:

- Reduced manufacturing cost (often offset by the cost of the VPI process)

- Fast to install due to high level of flexibility

- No scarf joint at end of coil slot straight meaning the straight length can be reduced

- Reduced risk of voids in the end winding

- Homogeneous insulation & bracing

- Gives good insulation resistance

- Inherently Resistant to moisture & chemicals

VPI Disadvantages:

- Cost of buying and maintaining the VPI equipment and materials such as tank and resin

- Only one resin type can be used in the VPI process since the complete stator and winding is impregnated in one process. To maintain stability of coil in slot the resin needs to be a rigid thermo setting resin

- Multiple processing required for good surface finish

- After 15 -20 years service the rigid resin can cause cracking in the endwinding due to the frequency related movement

- Maintaining the coil parallel in the slot portion can be difficult (increasing the risk of partial discharge)

- Due to differential expansion the coil to coil bracing in the endwinding can result in loosening of the bracing between coils which will require regular rectification during the life of the machine

- There are a range of resins used in the VPI process The lower viscosity resins used by manufactures are difficult to maintain and need a high resin turnover

- Retaining resin in the stator winding during curing generally requires stator rotation during the curing process, which is easier for manufacturers who wind a stator core pack before inserting the cured stator core pack into the stator case

- Since the complete stator needs to be processes the VPI vacuum/pressure vessel needs to be large enough to accommodate the stator case

- Stators which have been VPI impregnated are very difficult to repair.

- Complete rewinds are more expensive due to difficulty of removing the old winding This becomes a major issue for machines which can only be rewound on site

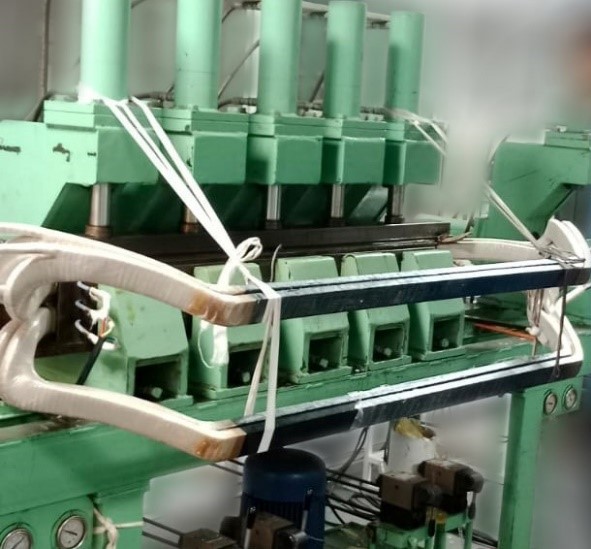

Armature / Traction Coils

We can produce high-quality AC-DC armature and traction coils with quick turnaround times and delivery anywhere in the world.

We create and provide a wide range of replacement and custom coils for the water, transport and power generation industries, making Preformed Windings an invaluable contact when it comes to repairing electric motors.

Insulation Systems:

- Un-pressed Resin Rich

- Vacuum Pressure Impregnation (VPI)

Conductor Materials:

- Copper Grade C101, BS1432, Cond “O”

- Enamel

- Enamel / Dacron

- Enamel / Mica

- Enamel / Glass

- Nomex

- Glass Lap / Glass Braid

- Kapton

Winding Kits

We can provide windings kits with all of the sets of coils we manufacture. The vast majority of our customers select this option to ensure, on arrival of their coils, they have everything they need to install them. This also ensures that the items in the winding kit are suitable for the application and eliminates the requirement to outsource winding kits separately.

A typical winding kit consists of:

- G11 wedge

- Magnetic wedge

- G11 packing strip

- Conductive packing strip

- RTD + RTD strip

- Cable

- Mica tapes

- Terylene tape

- Epoxy felt

- Blocks

- Brazing rod

- Resin glass tape

- Sealing tape

- Epoxy loaded rope

- Dry rope

- Side ripple spring

- Top ripple spring

- Dry felt

- Conductive fleece